Performance Forming With EPS

Structural Suspended Insulated Concrete Floor/Roof/Deck System

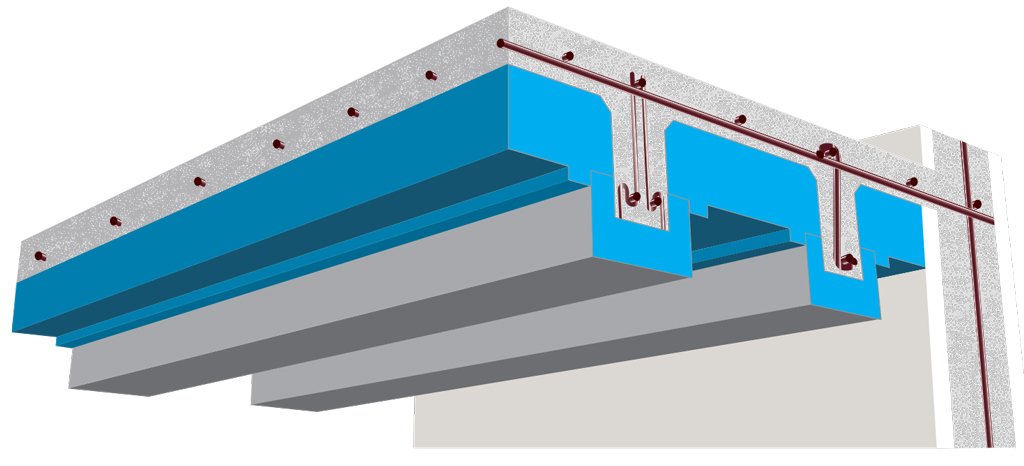

The Fortruss System is a stay-in-place concrete forming system used for suspended concrete floor assemblies and roof/ deck systems for residential and commercial construction, while providing excellent insulation value and superior acoustic performance. Three components make up Fortruss; Beam Forms, and Deck Panels, and patented Triple-Chairs for reinforcement support. The Beam Forms consist of EPS stay in place form, complete with a galvanized jacket on the sides and bottom. This provides not only form support but attachment surfaces for mechanical and electrical trades. Beam Forms are available in standard lengths or can be ordered in exact lengths for job specific installation. Beam Forms can be site cut with common tools to allow simple installation in non-standard applications.

The Fortruss System is a stay-in-place concrete forming system used for suspended concrete floor assemblies and roof/ deck systems for residential and commercial construction, while providing excellent insulation value and superior acoustic performance. Three components make up Fortruss; Beam Forms, and Deck Panels, and patented Triple-Chairs for reinforcement support. The Beam Forms consist of EPS stay in place form, complete with a galvanized jacket on the sides and bottom. This provides not only form support but attachment surfaces for mechanical and electrical trades. Beam Forms are available in standard lengths or can be ordered in exact lengths for job specific installation. Beam Forms can be site cut with common tools to allow simple installation in non-standard applications.

The Deck Panel consists of an EPS panel that interlocks between and above the beam forms to create a level floor deck with integral beams as 24” centers. The standard Deck Panel creates 15” total floor deck depth combined with the 4” concrete floor slab and can span up-to 26 feet. For longer span applications deeper Deck Panels can be supplied creating deeper beams.

Once the Fortruss System components are installed including Triple-Chairs standard reinforcement steel is added to the beam voids. Reinforcement varies depending on design loads and is to be specified by a qualified structural engineer on a job specific basis.

The Fortruss System’s advantage over other methods is its ability to provide the structural component of the floor without requiring the slab to be placed at the same time. The EPS Deck Panel, once beams are cast, provides a strong stable floor deck to continue building the next level. This not only saves time but requires only a fraction of the bracing for support during casting and curing. The Fortruss System can also be poured including the floor slab as in other systems, however there are many advantages for both the system installer and the trades to follow; all benefit from placing the structural beams separate from the floor slab.

Benefits to Consider…

- Builder friendly

- Energy efficient

- Sustainable

- Light weight

- Structural beam can be poured separate from finished slab

- Cost competitive

- Less bracing, faster completion time, less cost, no cranes

- Trade friendly installation of electrical and mechanical systems using conventional methods

- Controlled environment making decorative concrete floor finishes possible

- Can reduce or eliminate basement tele-posts and footing pads

- Can span up-to 40 feet single-span application

- A fire-resistance rating

- Superior acoustic performance